For IPC laboratories and online monitoring at the tablet press

UTS 4.3

Introducing the UTS 4.3: The Next-Generation Tablet Testing

Solution. Elevate your production capabilities with the UTS

4.3, a state-of-the-art, fully automatic tablet testing system

that builds on the robust foundation of the acclaimed UTS 4.1.

Now featuring an IPC version, the UTS 4.3 is revolutionized

with a database-driven, intuitive, all-in-one touch software,

designed to streamline your operations. Its modular software

functionality can be customized to meet your unique needs

and requirements, ensuring a perfect fit for your production

line.

Functionality

The UTS-Series splits into various models, all tablet tester models are testing the main physical parameters of tablets:

Weight

Thickness

Hardness (breaking force)

Diameter / Length

Width (optional)

With the Ph21 software the system becomes 21 CFR Part 11 compliant.

For challenging oblong tablets, incorporate the globally

acclaimed Oblong Centering System (OZB) for unmatched

precision.

Enhance your connectivity and control with the UTS 4.3’s new

all-in-one connection line, enabling direct control from the

tablet press for unparalleled efficiency. Choose to manage

sampling via the production machine or the advanced PH21

software solution for flexibility and control.

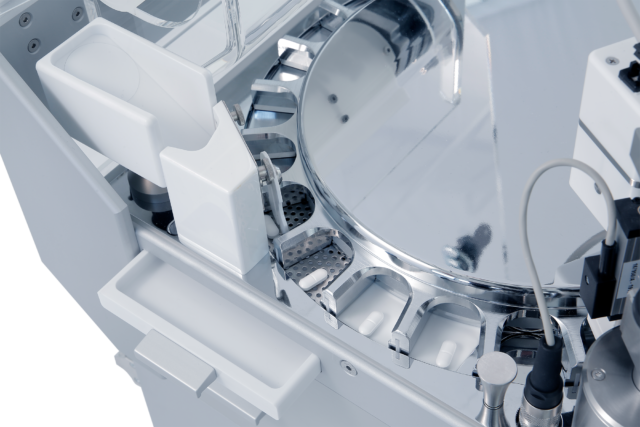

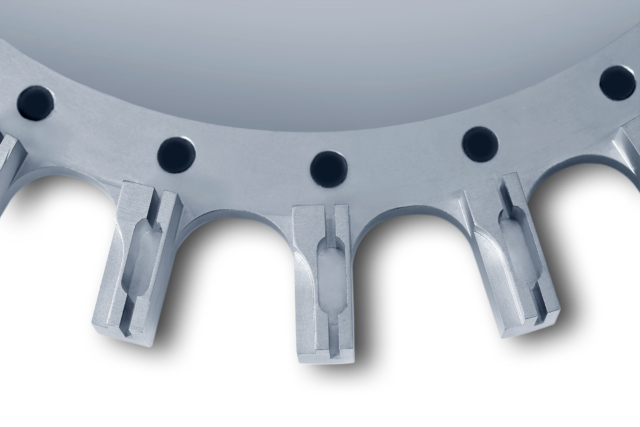

Three-stage dedusting

In the patented feeder chute which separates the tablets, tablets are also dedusted before testing. After the separation the tablets are fed one by one on a slide into the starwheel (star-shaped transfer element). Each tablet is detected by a dust-insensitive sensor.

Two additional tablet dedusting sections after the separation, keep the tablet testing stations clean and guarantee reliable test results.

Remaining dust and debris are collected in a special dust container under the separation slide.

Self cleaning feature

To keep the track where tablets are moved through the testing stations clean, inside the starwheel are 24 PTFE scrapers shuffling dust and tablet crumbs to the waste bin.

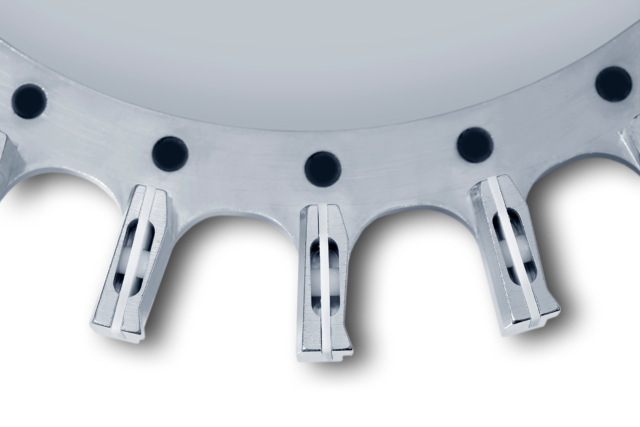

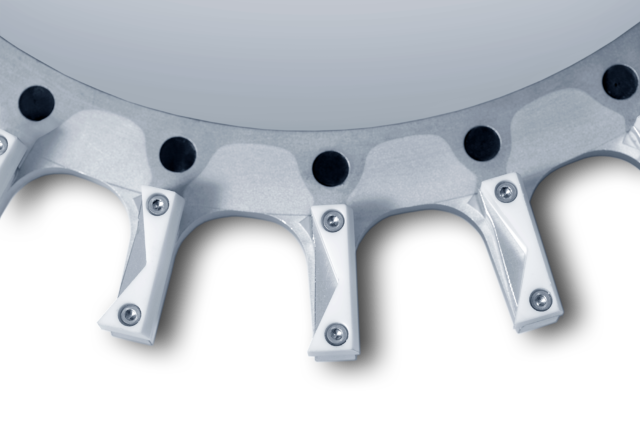

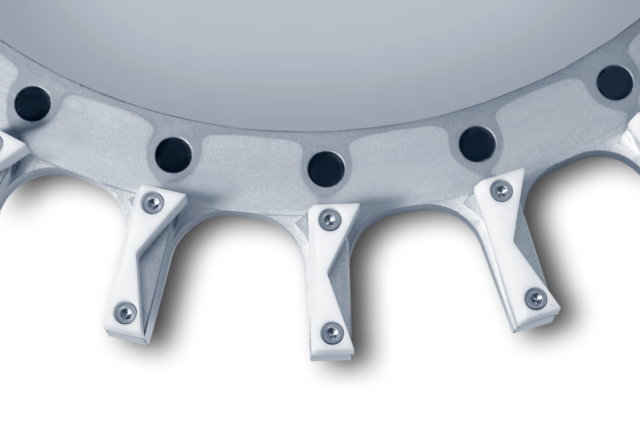

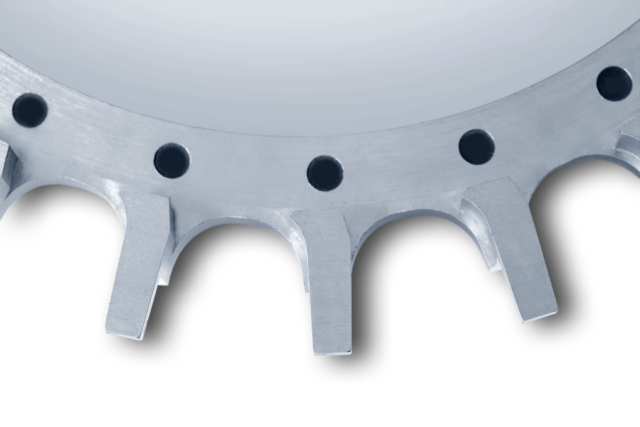

Positioning

The smart design of the transport starwheel alignes, centers and transports the tablets through the different measuring stations: weight, thickness, diameter and hardness.

Handling of unusual tablet shapes

The transportation starwheel which moves tablets through the different testing station is available with many different executions and can be customized.

Online tablet testing at the tablet press

Use the Kraemer UTS4.3 as an online monitoring device connected to your tablet press or capsule filler. Sampling can be initiated either from the production machine or via our Ph21 software.

Customized solutions

We provide special solutions for specific customer requirements. Here are a few examples of customized Kraemer UTS models:

S7 – With special feeder for tablets up to Ø 25 mm

S8 – For tablets up to Ø 50 mm

S9 – For mini-tablets

S16 – With conveyor belt feeder and 5-way sorting diverter

S17 – With 2-way sorting diverter

S20-FC – Dust-proof with single tablet feeder

Choose your favourite options on the bottom of this page!